AirTreatment

Air Dryers:

Air dryers are essential in compressed air systems for several reasons:

Moisture Removal:

When air is compressed, it becomes saturated with moisture. Air dryers remove this moisture, preventing it from condensing in the system

Preventing Corrosion: Moisture can cause corrosion in pipes, tanks, and pneumatic tools, leading to damage and reduced lifespan of the equipment.

Improving Efficiency:

Dry air ensures that pneumatic tools and machinery operate smoothly without clogging or performance issues.

Enhancing Product Quality:

In industries like food production, pharmaceuticals, and electronics, moisture in compressed air can spoil products or affect their quality. Air dryers help maintain high standards by providing clean, dry air.

Avoiding Freezing:

In outdoor applications, moisture in compressed air can freeze, causing blockages and failures in the system.

Refrigeration Air Dryer:

Refrigerated Dryers play a crucial role in compressed air treatment by effectively removing moisture from the air. Refrigeration dryers assist in maintaining the quality and reliability of the compressed air, ensuring it is suitable for various applications where dry, moisture-free air is crucial. By protection of equipment and processes, Refrigerated Dryers contribute to operational reliability, reduced maintenance costs, and boosted overall productivity in compressed air systems. With ranges offered from 25-5000 SCFM at 3°C pressure Dew Point. Offering various brands and models such as high temperature to best suit your facilities demands.

Desiccant Air Dryer:

Desiccant dryers are designed to efficiently dehydrate compressed air to dew points as low as ISO 8573-1 Quality Class 1 (-94°F/-70°C) Industries such as pharmaceutical manufacturing, laboratories, hospitals, food packaging, paper, and powder painting with low dew point requirements, utilize desiccant air dryers. Ranges offered are 40 to 5400 scfm. With our various offered brands we can best recommend the most suitable desiccant dryer for your facilities unique requirements. We offer desiccant dryers in the following configurations:

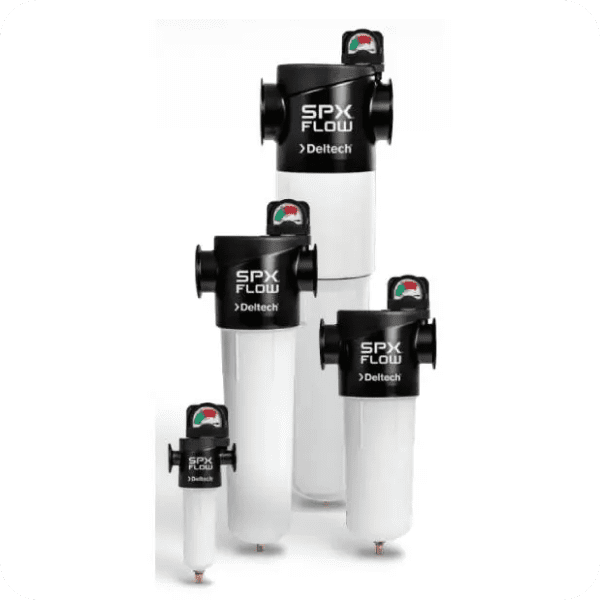

Filtration:

We offer a wide range of compressed air and gas filtration products for use in almost every industrial environment. Manufactured in cast aluminum alloy, the optimized modular filter design ensures high performance, and ease of installation. A unique material construction minimizes pressure drop and improves energy efficiency, something that is crucial in today’s economic climate.

Our Brand of Filters

Condensate Treatment

Oil/water separators are crucial in compressed air treatment for environmental and operational reasons. When compressed air is used in industrial processes, it often accumulates oil and other contaminants. These pollutants, if not properly separated, can lead to environmental harm when the air is eventually vented or discharged. Oil/water separators address this issue by efficiently separating oil from the water condensate, thereby reducing the risk of contaminating waterways and soil. This separation is not only environmentally responsible but also complies with stringent environmental regulations. Moreover, from an operational perspective, these separators extend the life of compressed air systems by preventing the buildup of oil and other contaminants in the system, which can cause damage and reduce efficiency. By ensuring the purity of the discharged air, oil/water separators play a vital role in maintaining the overall health and sustainability of compressed air systems in various industrial settings.

QWIK-PURE® CS/iCS Oil-water Separators

Intelligent Operation

Flow-regulated control of the unit at all times using capacitive sensor technology, complete visibility of the operational status, and data recording with an IIoT-ready controller.

Patented Functionality

The revolutionary principle of using very low pressure compressed air to push condensate through the cartridge in concert with the controls is exclusive technology.

Environmentally Safe

QWIK-PURE cartridges are hermetically sealed and are safe for sanitary landfills because the oil is securely trapped in the adsorption material, and sealed.

Quick and Easy Service

Patented quick disconnect cartridges combined with a lightweight filling material make installation and service simple, flexible, and clean.

Modular Expansion

A future-proof solution for any application that effortlessly expands and can accommodate up to 3,300 scfm in a compact space.

Drains:

Condensate drains are crucial part of air system component, help to remove condensate separated from the system.

No Loss Drain:

Bekomat no loss drains are offered in various sizes; we can help you sizing the correct drain for your application. Here are some of the advantages of the Bekomat drains.

Timed Auto Drain:

Timed Auto controlled drains are available in various configurations, constructed to drain condensate from air compressors, moisture separators, filters, air dryers and drop legs in a compressed air system. Timed Auto Drain also offered in high pressure.

Air receiver

Air receiver is an integral part of any compressed air system. The main purpose of this is to act as temporary storage to accommodate the peaks of demand of the plant. Air receiver is offered in vertical and horizontal configurations.

Vertical Compressed Air Tanks designs essential for maintaining pressure stability and buffering sudden demands in compressed air systems, are taller than wide, offering a compact footprint suitable for confined spaces with adequate ventilation.

Horizontal Compressed Air Tanks are used in low-profile installations or areas with limited vertical clearance.

Air receiver size: 10 to 10000 gallons

Pressure rating: 160 psig, 200, psig, 300 psig and heigh pressure air receiver